about us

Our mission

Rooting on our solid expertise in the field of industrial and academic research on composite glass, we propose ad-hoc solutions for innovative transparent surfaces in space applications.

We aim at providing designs, experimental tests and prototypes of windows for space applications, but not only this: we can deliver solutions for transparent structural elements in general, for example for submarine or architectonic applications.

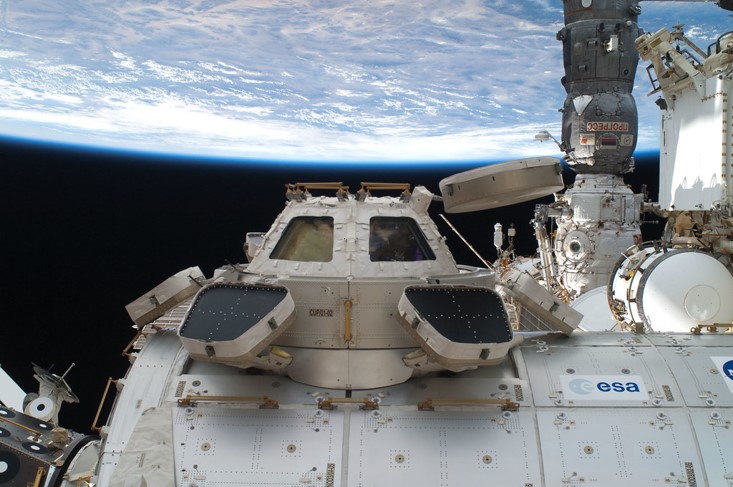

Glass surfaces in space: a challenge

How to design reliable, lightweight and durable windows for next generation space stations and space ships? Historically, transparent surfaces for space applications always posed many difficulties, because of strict constraints on weight, resistance to impacts with micro meteoroids, resistance to thermo-mechanical fatigue and radiations. We propose innovative solutions to this challenge.

What we do

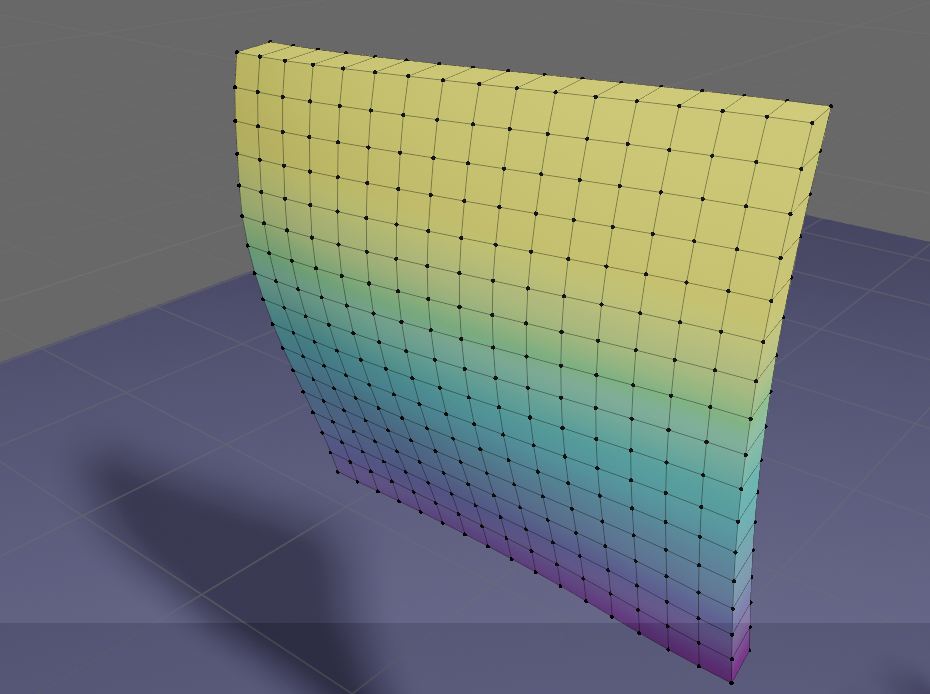

We design glass panels, frames and gaskets using parametric associative 3D CAD, also developing custom algorithms for advanced B-Rep surfacing.

We perform thermo-mechanical analysis of multi-layer heterogeneous glass structures with state of the art FEA. We also develop custom FE elements.

We deal with complex simulation scenarios by impementing custom in-house simulation software, using C++, Python, C# and other languages.

A team that can be trusted

We have a long track of industrial and academic research. Our research topics include the mechanics of brittle and quasi-brittle materials, with emphasis on structural glass; analytical modelling of structural composites, including layered and/or curved structural elements; time-dependent response of composites with viscoelastic components; homogenized approaches for cracked composites; fracture and damage mechanics; design of lightweight and special structures; analytical and semi-analytical study of thermal stress in monolithic and composite elements; advanced numerical modelling of layered structures; development of Discrete Element Method (DEM) software for the analysis of multi-bodies in unilateral contact.

Testimonials

We aim at creating transparent surfaces, larger and lighter than those obtainable with current technology, fulfilling extreme requirements of durability and resistance.